The Major Trends Of The Manufacturing Industry 4.0

It is now a fact that an epochal change is underway in the global industry, known as the fourth industrial revolution. As has happened in the past, factories are turning towards different processing systems based on new technologies.

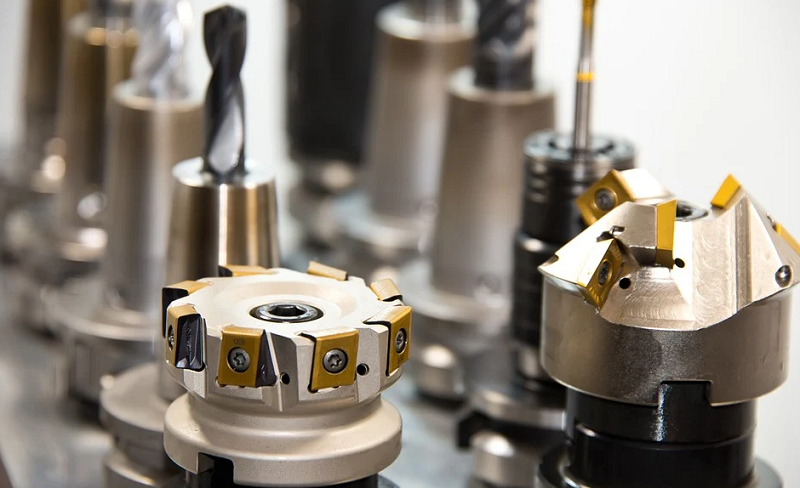

The methodologies brought about by the technological transformation, also known as Industry 4.0, will have an impact above all on manufacturing, that is, on the production and transformation of the product. The production processes of companies like ceratizit.com, in fact, are (and will be) increasingly automated. A crucial role will be played by collaborative robots, machines able not only to perform tasks automatically and quickly, but also to interact and work alongside the traditional workforce.

The factories will also open their doors to virtual and augmented reality, technologies that at the moment seem to belong to other sectors. Here are some of the main trends that will change the manufacturing industry.

Virtual and augmented reality

Both the two technologies will be destined to demand more and more attention in Industry 4.0. Even if their use is still in an embryonic phase, virtual and augmented reality will be decisive. They will enable companies to achieve both production and cost benefits.

Virtual reality, for example, can be used to carry out reliable simulations. We think of the automotive sector, where companies are forced to create many prototypes. With virtual reality it will be possible to recreate production processes quickly and verify potential defects, moving 360 degrees.

The same goes for augmented reality, a technology that allows you to project virtual images in the real world. We always remain in the automotive sector. If a component breaks during one of the assembly phases, the employee can use augmented reality to understand how and where to intervene, without resorting to any instruction manual.

3D printing

The fourth industrial revolution changes the company also as regards the creation of a piece. In fact, more and more industries are using 3D printing. The benefits are many. First of all, 3D peripherals allow you to reduce the material used to produce a piece. This means reducing both costs, but also waste (and therefore emissions as well). Furthermore, they are very practical as they halve production and delivery times. And they help factories improve the relationship with their customers.

Automation

As mentioned, Industry 4.0 will above all be automated. The change will affect many sectors, in addition to manufacturing. At the moment, the companies that are using the robots are mainly automotive and electronic ones, which will soon be followed by other companies as well. In particular, this year will mark a watershed between the old production systems and the new ones. Using robots means making manufacturing processes more efficient and faster. And despite the fears, machines will not take the place of man, but will create new jobs.

Cloud systems

Cloud computing systems will also be decisive, which will allow the company to replace machines no longer necessary for archiving and will simplify the plant’s IT network. In addition, they will represent the container where Big Data, aggregate information collected by robots, intelligent sensors and objects always connected to the Internet of Things will be stored. Much of a company’s success will depend on being able to read and interpret all of this data.